Prologue to Capacity Management and Availability Management (CAM) The capacity and Availability management field involves setting up and oversight of capacity and availability at a reasonable cost with proficient utilization of resources Various levels perform this process in an organization across allied services Download This Template It includes and serves(For example, the initial capacity building plan targeted nationallevel GRZ staff; Business Capacity Management The capacity of teams, business capabilities and processes This can include human resources, equipment, infrastructure, facilities and technology For example, an operations team plans the resources required to boost production by

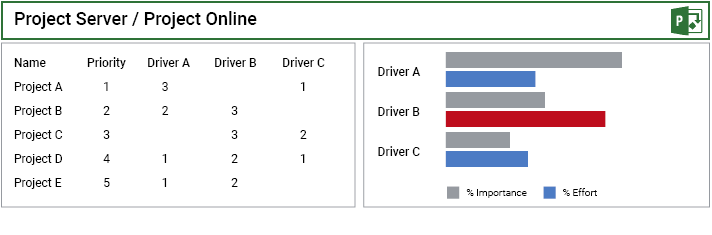

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

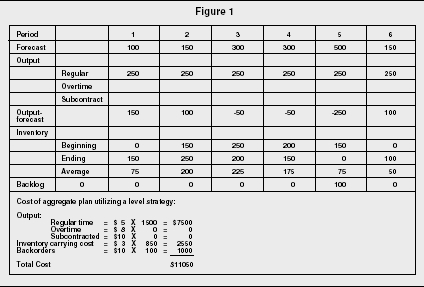

Level capacity plan example

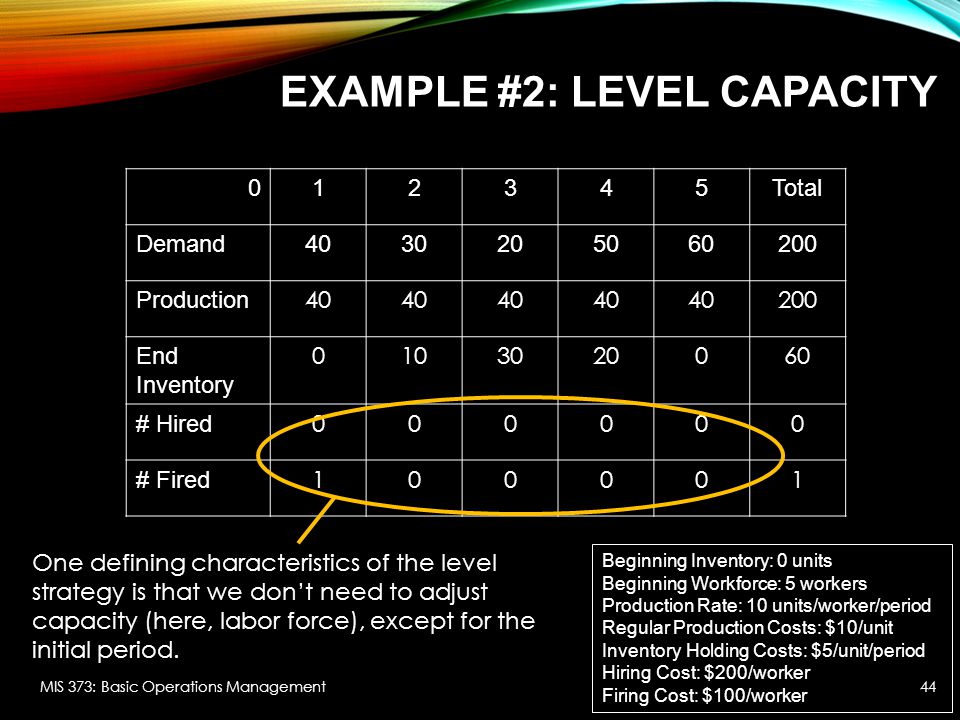

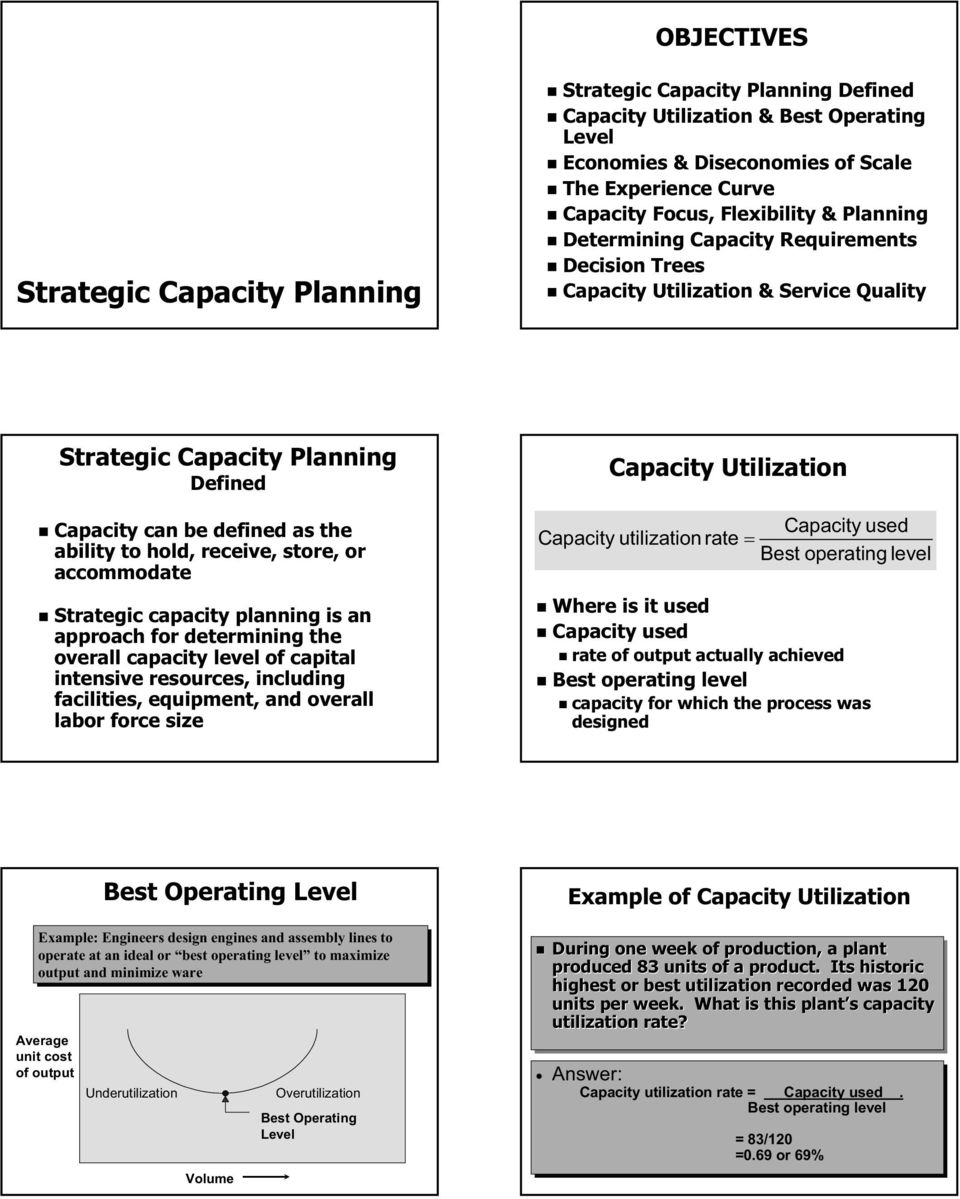

Level capacity plan example-Use break even analysis to evaluate capacity alternatives This module examines how important strategic capacity planning is for products and services The overall objective of strategic capacity planning is to reach an optimal level where production capabilities meet demand Capacity needs include equipment, space, and employee skills10 Annual Sales Plan Examples;An example of level capacity management could be the first step of the production of salt by evaporation (in Italy there is one industry like this in Salina)And the capacity level for each period that maximizes the firm's (supply chain's) profit over the planning horizon – Specify the planning horizon (typically 3 to 18 months) – Specify the duration of each

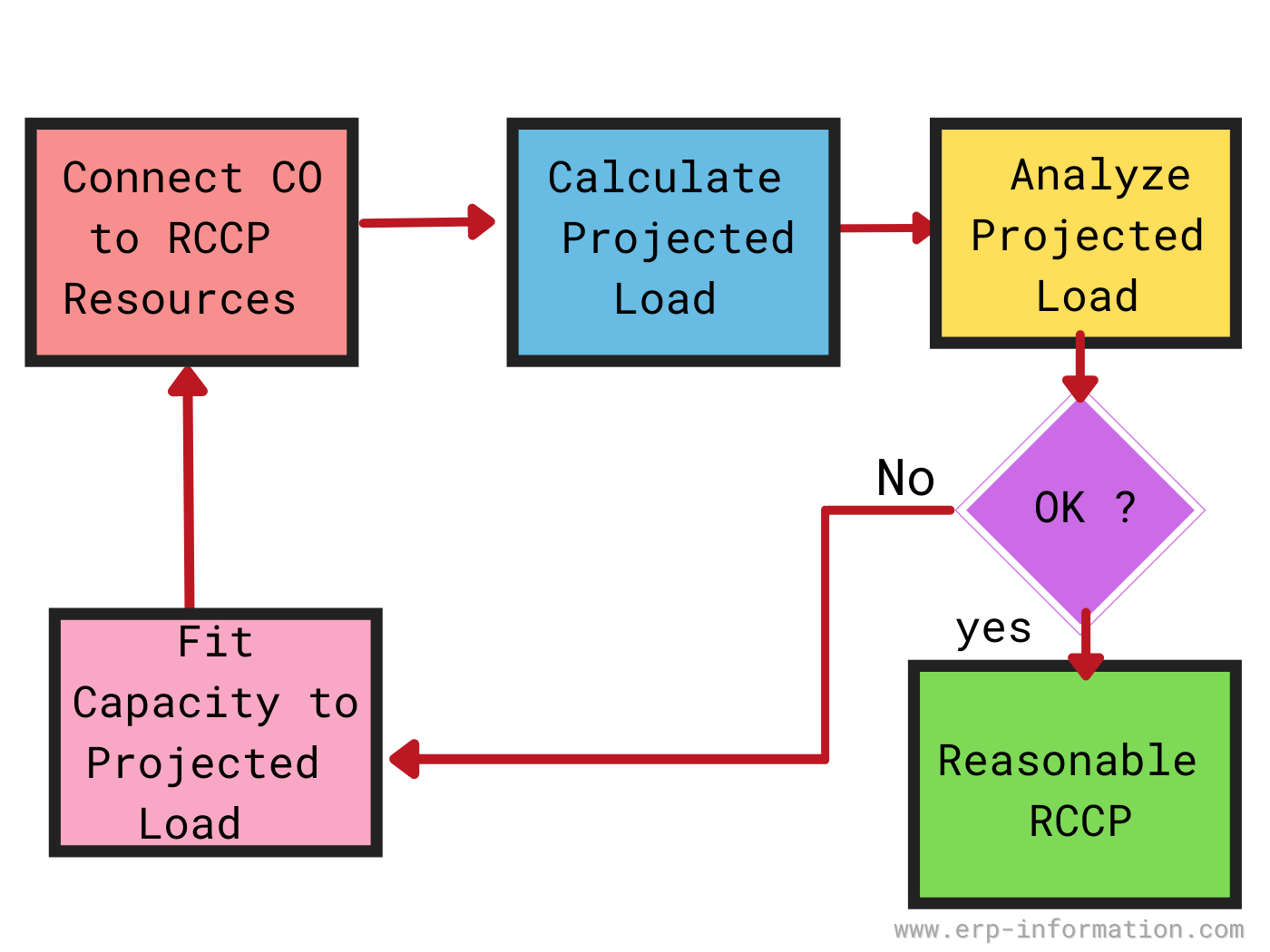

Demand And Capacity Management Decision Steps Download Scientific Diagram

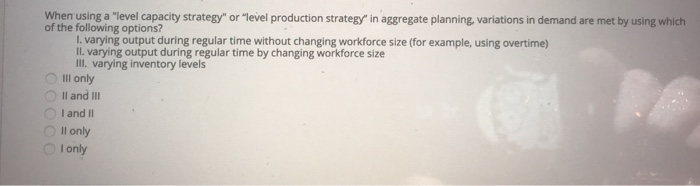

The level capacity strategy, the focus is on the process where product output remains at a somewhat fixed level and increases/decreases in demand are satisfied through strategic decisions of utilizing inventory (maintain buffer stock), outsourcing and backorders In comparison to level capacity strategy is adjusting capacity to followLevel Capacity Plan The inventory size is varied keeping the workforce size and utilization of work constant The number of workers ( working size) is kept constant throughout the time period under consideration During months of low demand the excess units required over the units produced are taken from the inventory 3 Examples of Production Capacity John Spacey, Production capacity is the volume of products or services that can be delivered by the operational resources of an organization Resources include factors such as land, labor, facilities, infrastructure and machines The following are illustrative examples of production capacity

Practical examples of models in capacity planning for different production modes include 1 Make to Stock (MTS) Make to Stock is common within discreet manufacturing and process manufacturing As these operations often have complex multilevel BOMs, capacity planning must include planning for subprocesses required to produce components9 HighLevel Project Plan Examples – PDF Highlevel planning is focusing on establishing your project's requirements and deliverables, and then tracking them over time Every time you estimate a new project and assign resources to it, you are actually creating a highlevel project planLevel capacity strategy The demand for any product is never constant It may change due to various reasons An operations manager has to plan in advance about the demand of the product He or she may have to use some strategies to meet this uneven and everchanging demand pattern These include pure strategies and strategy which uses a

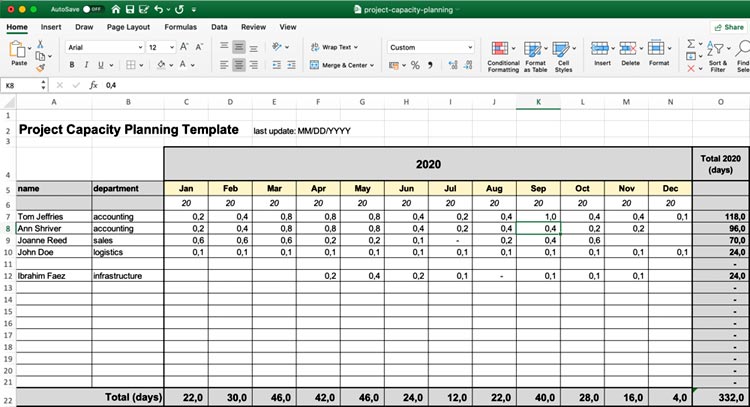

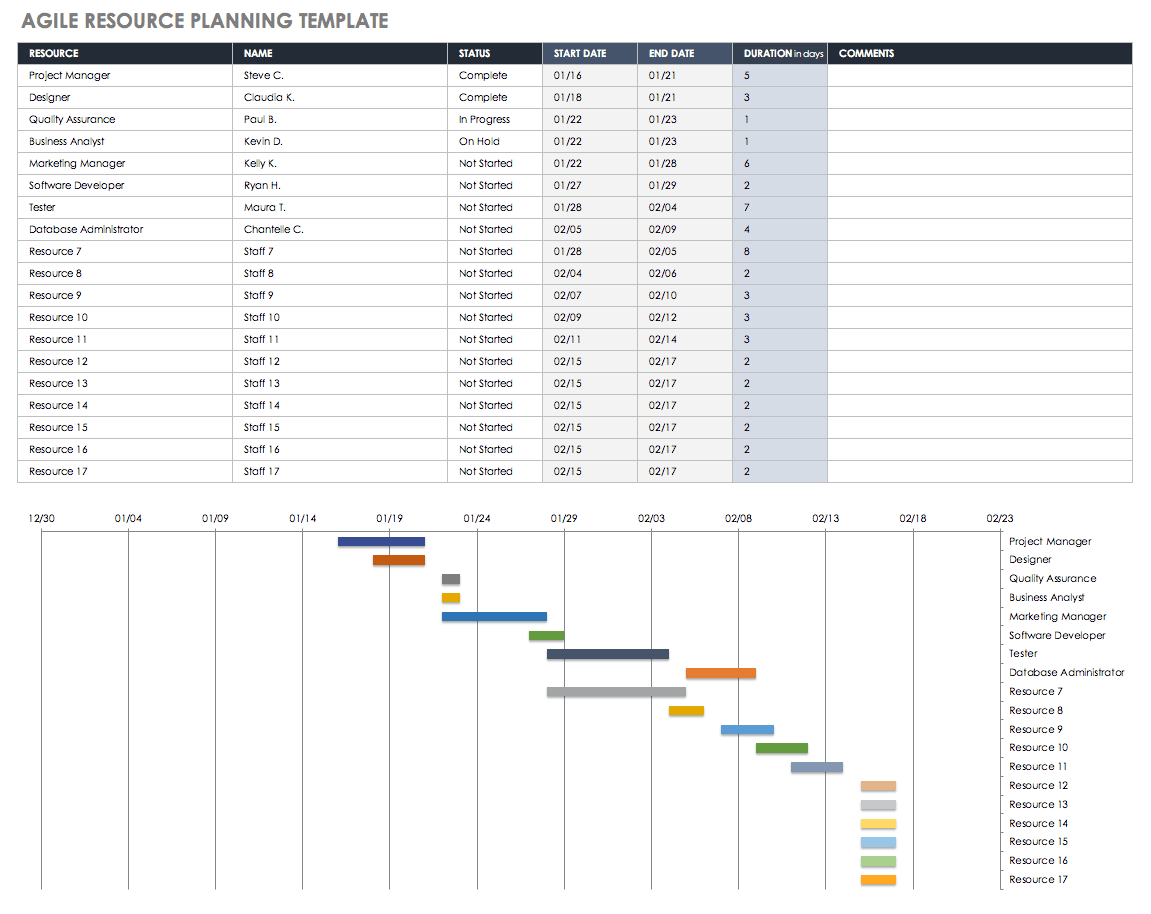

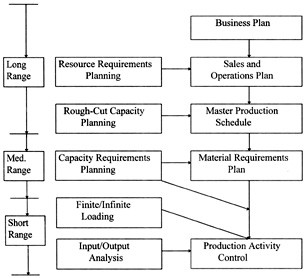

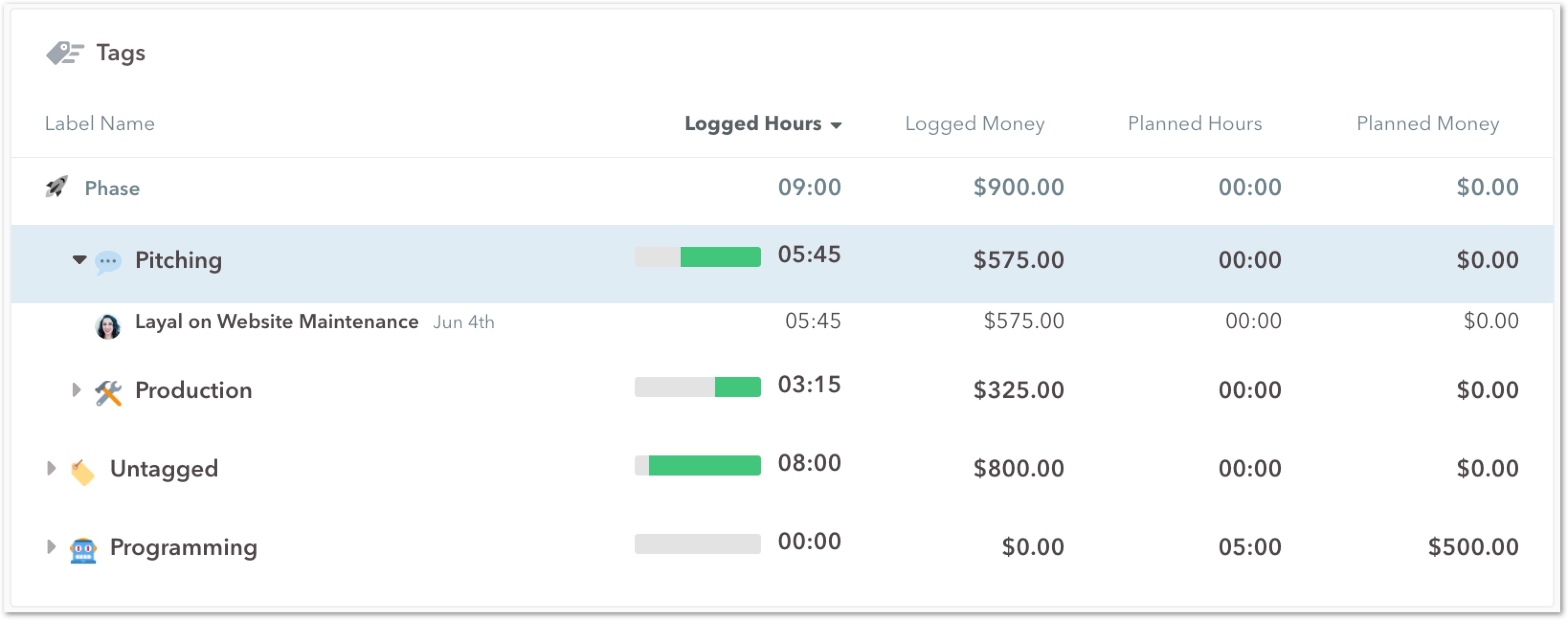

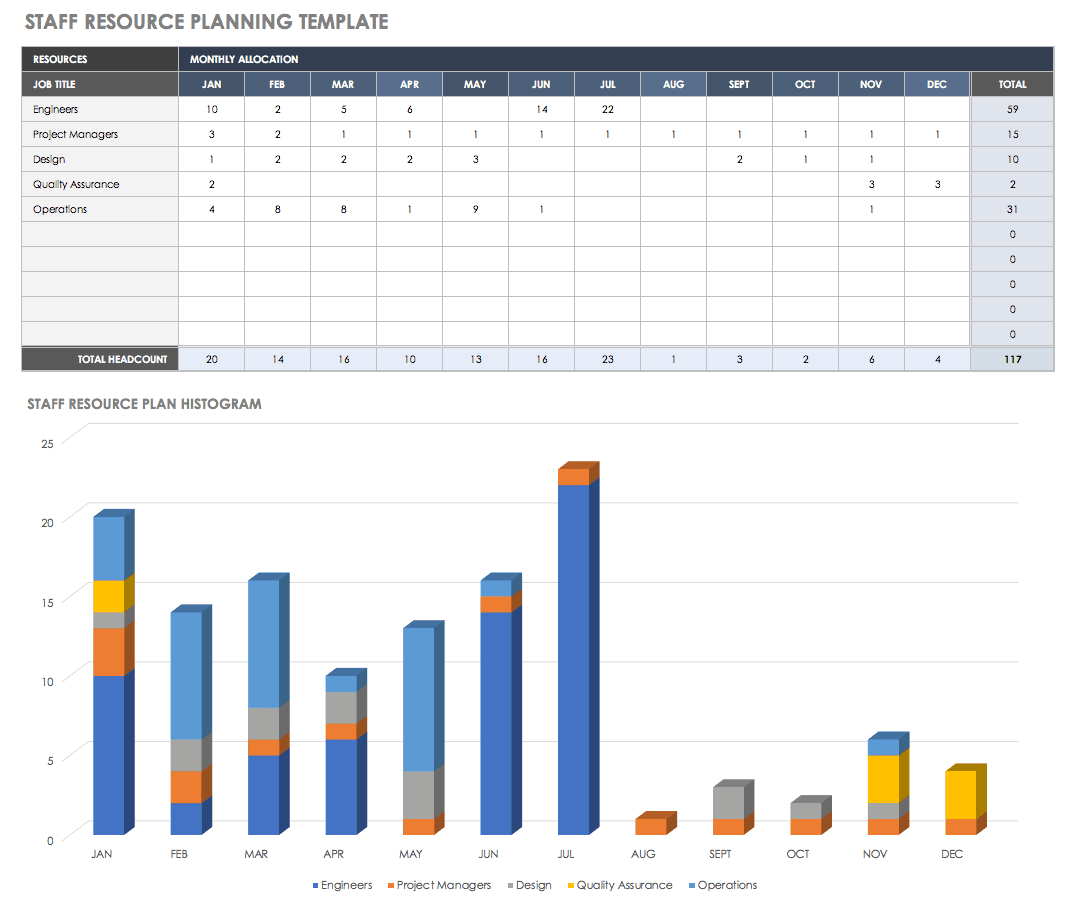

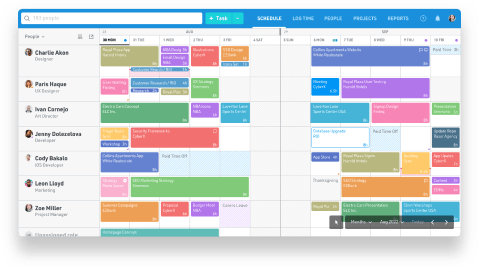

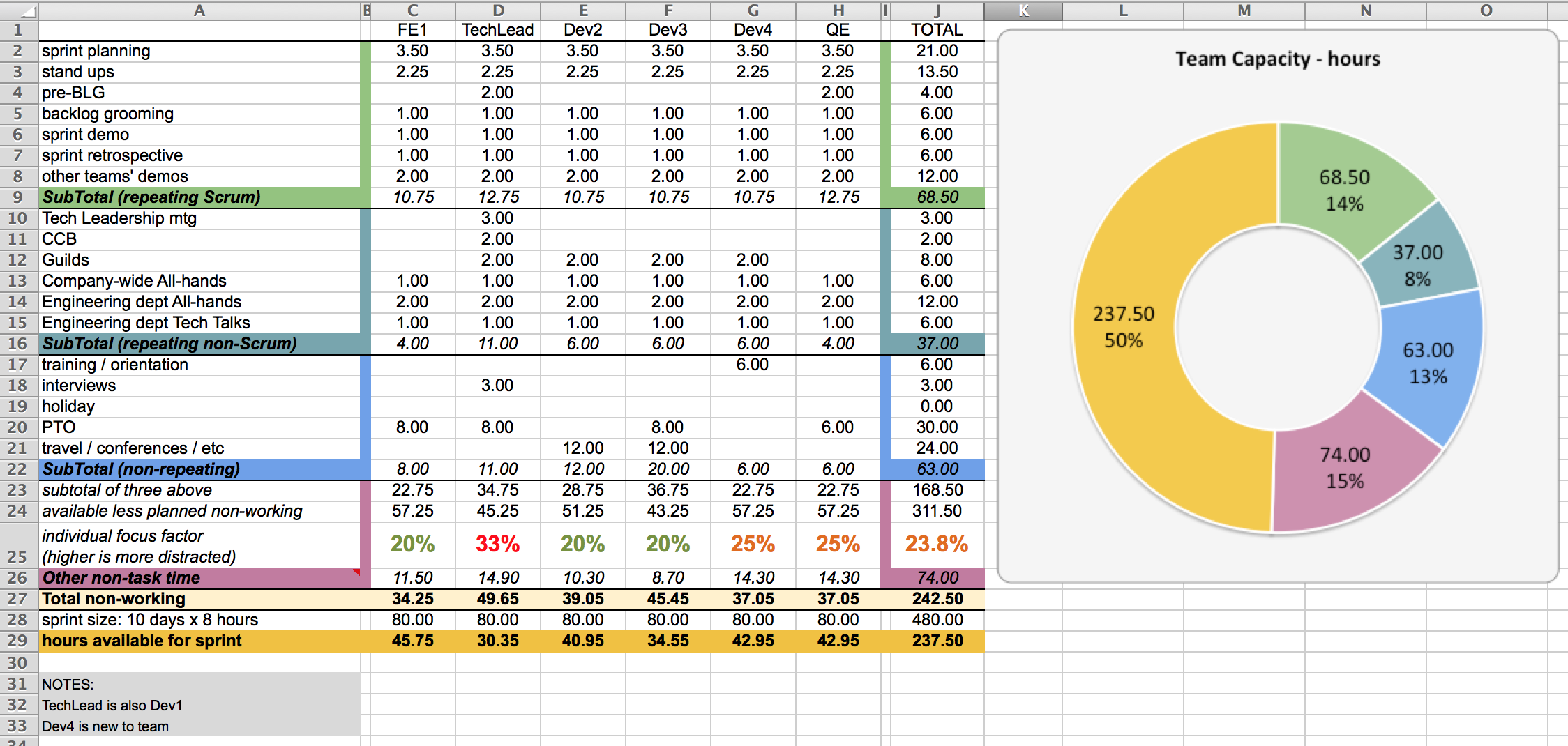

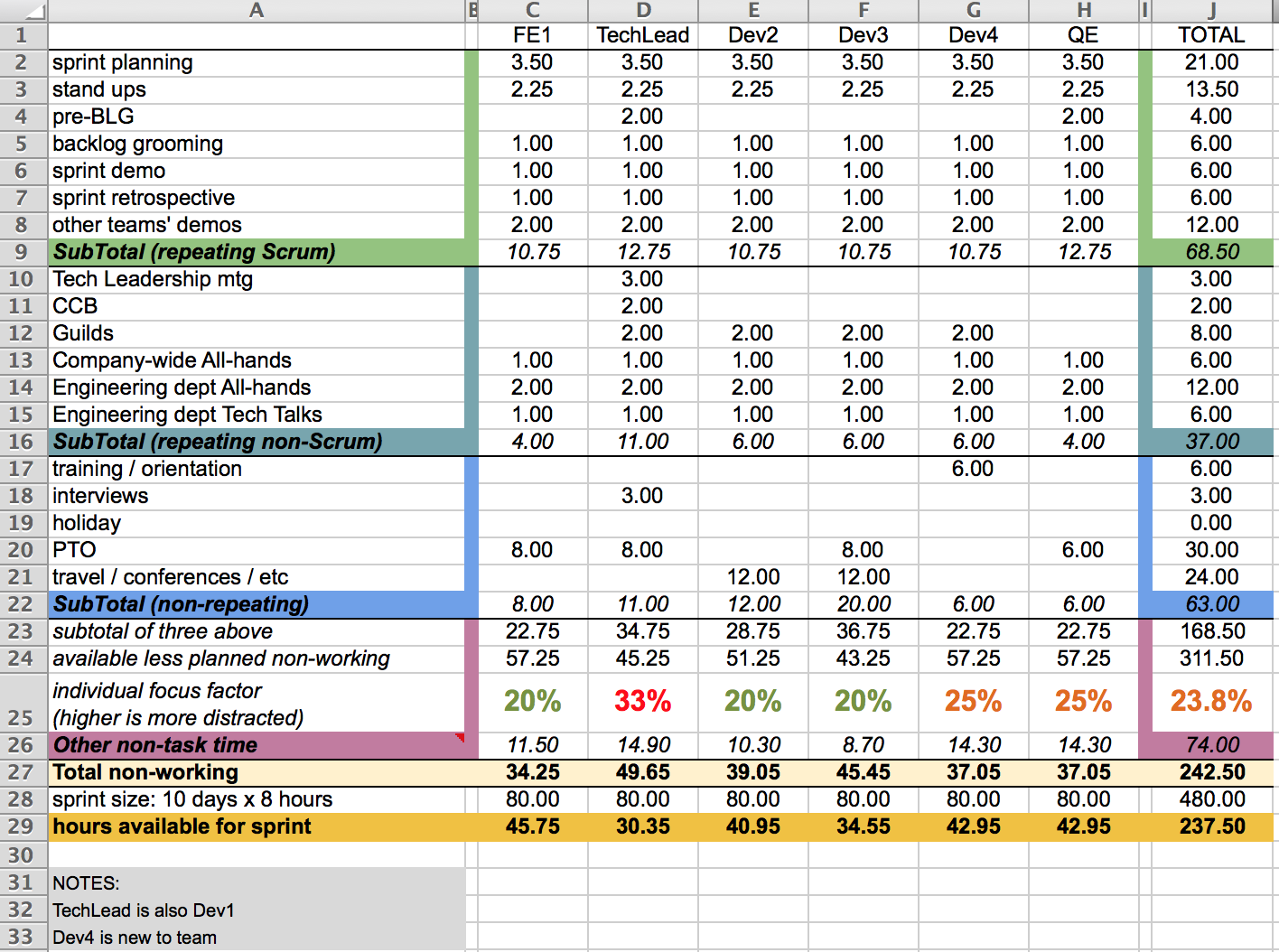

Capacity requirement planning forms part of the operational stage of the planning process and works in conjunction with a manufacturing requirement planning (MRP) system A detailed capacity requirement plan provides an operational level overview for the production cell and assists the operations manager with identifying all of the elementsUPMC St Margaret Hospital Surge Response Plan 1 LEVEL DEFINITION AND CRITERIA NEDOCS Score and Interpretation LEVEL 1 – 2 NEDOCS = 0 – 60 Not busy busy LEVEL 3 NEDOCS = 61 – 100 Extremely Busy, not overcrowded LEVEL 4 NEDOCS = 101 140 Overcrowded LEVEL 5 NEDOCS = 141 – 180 Extremely Overcrowded Level 6 NEDOCS = 181 – 0 Download Excel Template Try Smartsheet Template This resource capacity planning template includes a Gantt chart feature to visualize and plan resources for Agile software project sprints Use this template to chart software development resources by quantity and skill type (for example, PMs, analysts, developers, designers, product managers, administrators, etc)

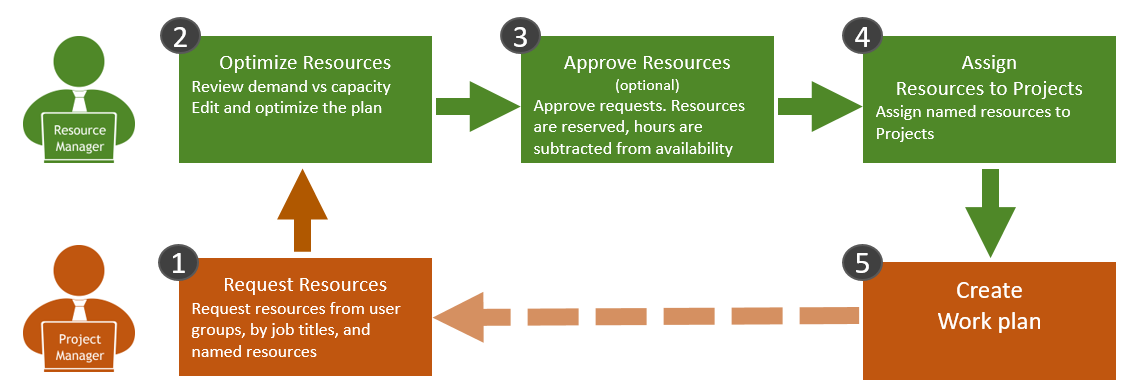

What Is Resource Management And Why Is It Important Planview

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

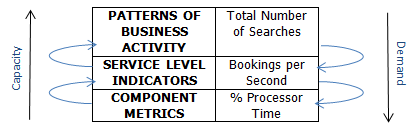

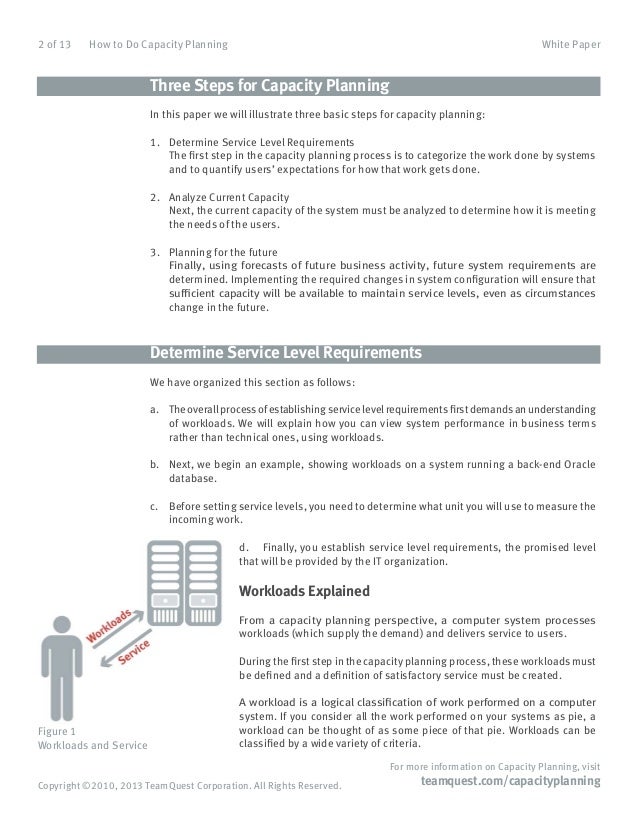

Production, Capacity and Material Planning a Production plan `quantities of final product, subassemblies, parts needed at distinct points in time a To generate the Production plan we need `endproduct demand forecasts `Master production schedule a Master production schedule (MPS) `delivery plan for the manufacturing organization Selecting a capacity alternative most suited to achieving strategic mission 17 THREE STEPS OF CAPACITY PLANNING 18 Determine Service Level Requirements 19 The first step on the capacity planning process is to categorize the work done by systems and to quantify users' expectation for how the work gets down Define workloads 211 Capacity Development Working Group (WG) Terms of Reference (June 10) 2 Organizational Capacity Assessment Sheet (version 2) 3 Individual Capacity Assessment Sheet (version 1 and version 2) 4 Sample of Programme Design Matrix (PDM) 5 Sample of Plan of Operation (PO) 6 Evaluation Sheet for final Presentation

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Rough Cut Capacity Planning Rccp Definition And 2 Types

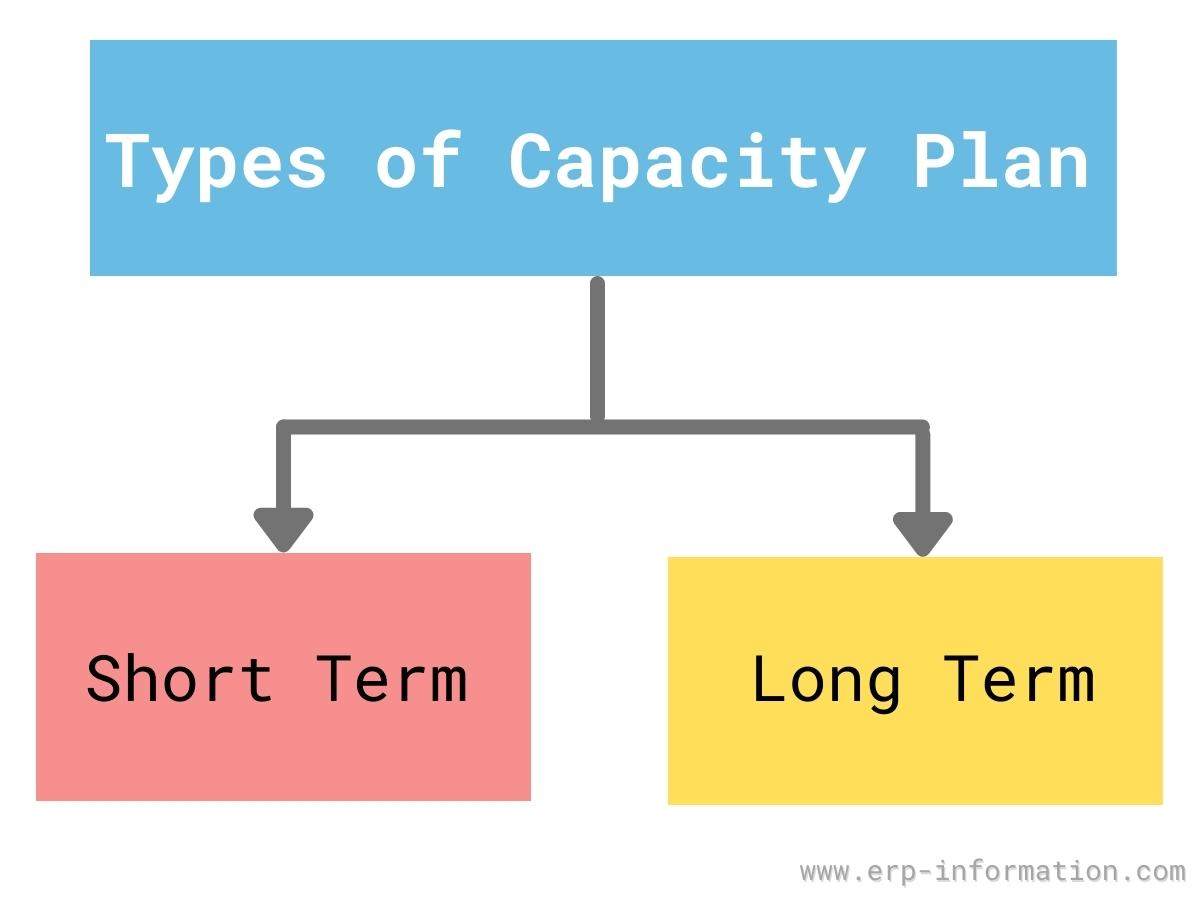

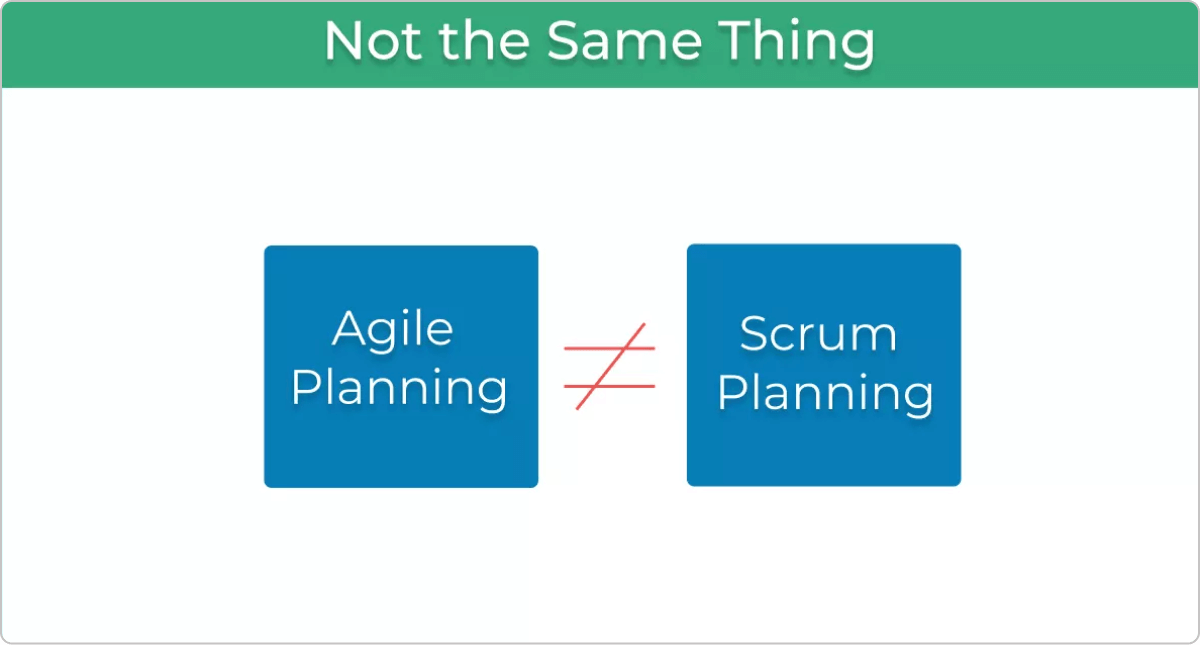

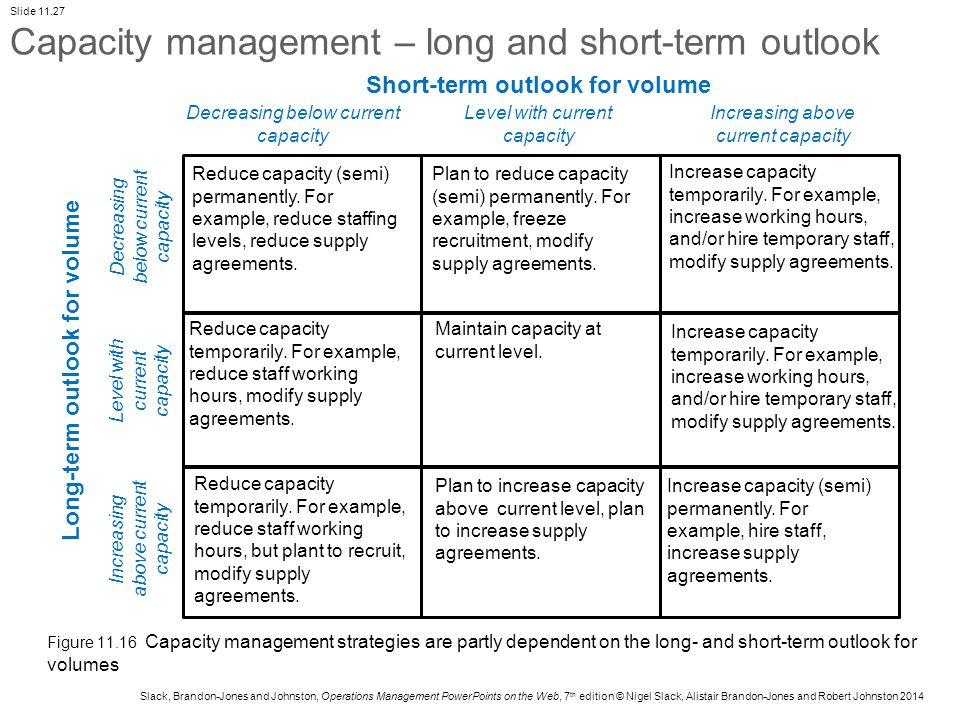

An approach to aggregate planning that attempts to match supply and output with fluctuating demand Depending on the product or service involved, the approach can incur costs by the ineffective use of capacity at periods of low demand, by the need to recruit or lay off staff, by learningcurve effects, and by a possible loss of quality The advantages include low storageStrategic capacity planning is essential as it helps the organization in meeting the future requirements of the organization Planning ensures that operating cost are maintained at a minimum possible level without affecting the quality It ensures the organization remain competitive and can achieve the longterm growth plan What is a level capacity plan?

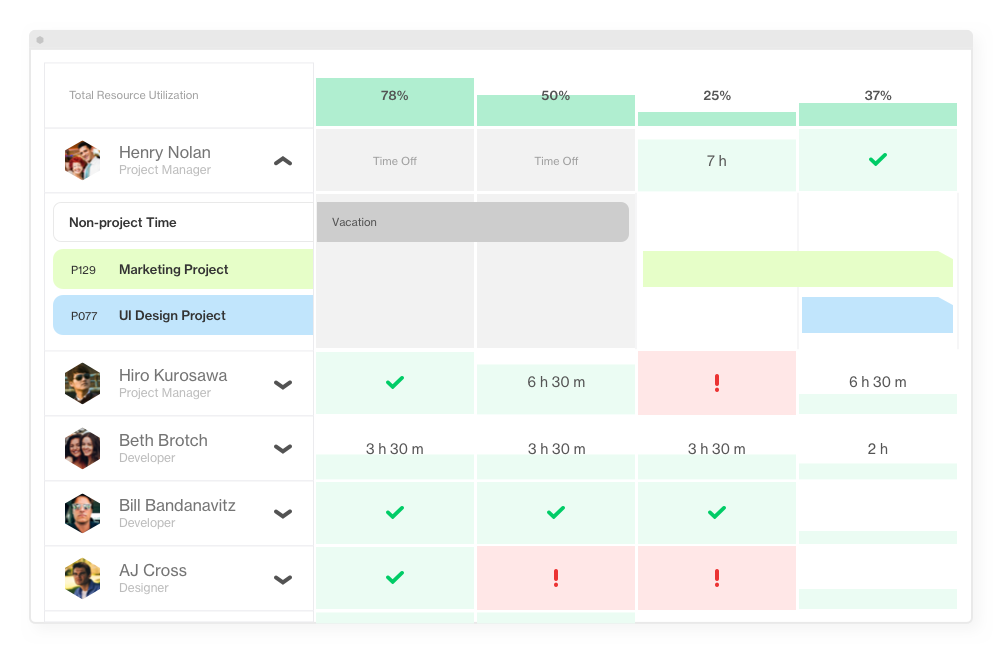

How To Do Effective Capacity Planning On The Scrum Team

5 Steps To Create A Tech Support Capacity Plan The Operations Blog

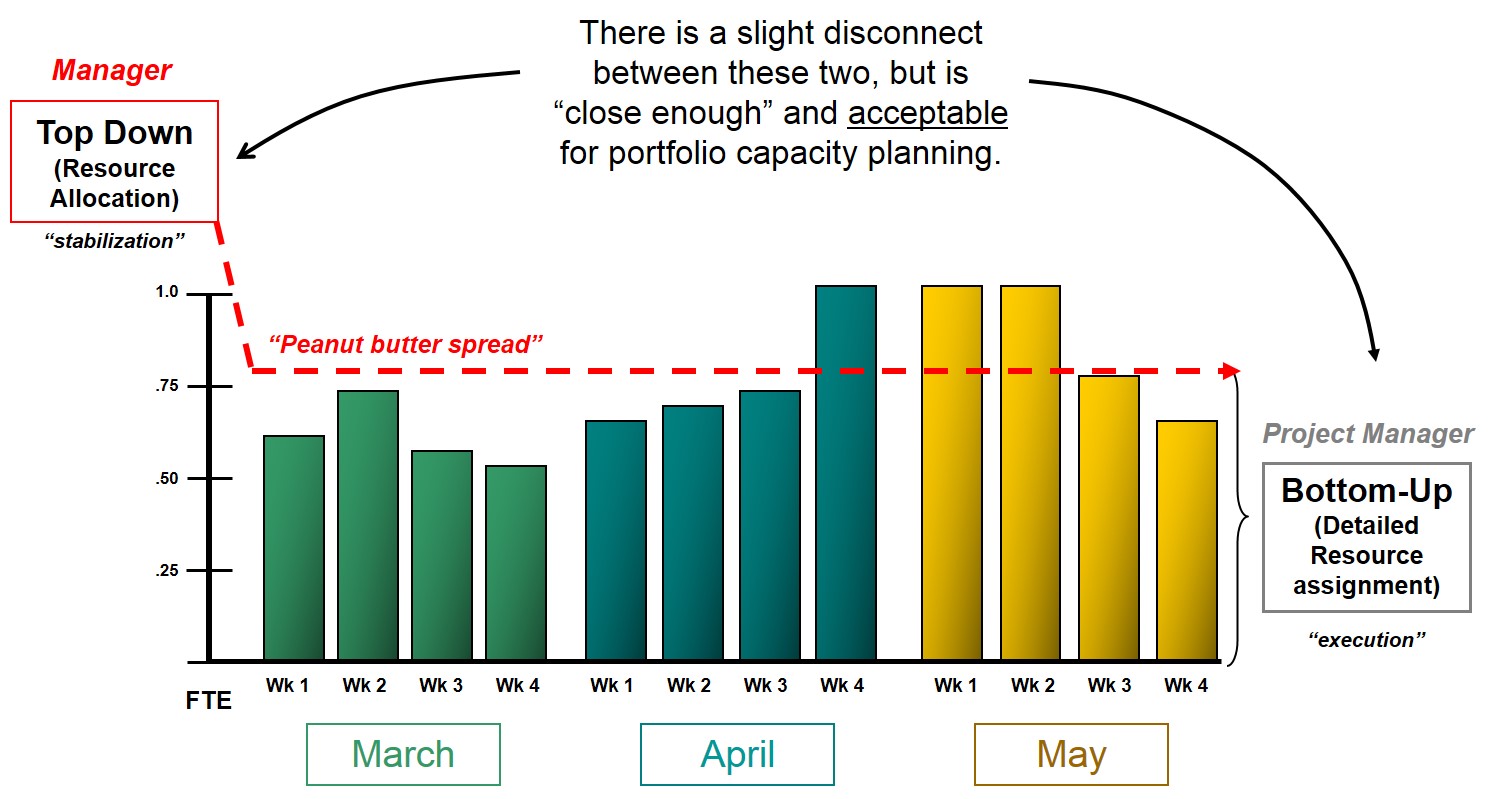

For example, a group of hospitals in a large urban area might agree that it is unnecessary for each to purchase expensive medical equipment for every ailment and that they ought to share capacityTo keep your capacity planning simple, you need to analyze your capacity plan at the team or skill level and not by analyzing individual resources Which means for example comparing how many project managers you need for your projects vs how many you currently haveThis method is a farcry from having an accurate substitute to replace Erlang for interval level forecasting, but it will get the job done for high level capacity planning As mentioned at the start of this article this is the first part of a two part series on capacity planning

Capacity Planning For Project Managers How To Plan Your Team S Time

Agile Planning Step By Step Guide Template Monday Com Blog

Purpose of Capacity Plan Provide the purpose of the capacity plan For example Capacity planning is an important part of infrastructure and deployment planning A capacity plan supports the goal of optimum, and cost effective, provisioning of organizational resources and services by matching them to business demands Capacity planning strategy involves the process used to determine the resources manufacturers need to meet the demand for their products or services The level of capacity directly relates to the amount of output in the form of goods and services manufacturers can produce to satisfy customer demand Capacity planning strategies can guideCapacity Plan Template Version Xx This Capacity Plan is an integral part of infrastructure and deployment planning It supports the goal of Service Level Agreements (SLAs), utilization reports, capacity modeling, and workload forecasts

Metron Capacity Management Capacity Management Guided Practitioner Satnav Capacity Plan 16 Of 17

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity Planning It's pprove/cancel projects"The level capacity plan satisfies high demand from existing stocks When demand goes below capacity, overproduction is stored as inventory in anticipation of higher demand in later months The disadvantage of this approach is that this tends to build in high stock levels and hence high levels of working capital are requiredCapacity is often measured in hours available to be worked by employees And in this context, "planning" is the act of scheduling employee hours against a fixed or expected amount of work Example A company has 10 employees Each employee works 40

2

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

Smoothing plan is best suited to situations where inventory carrying costs are low We will now present a simple example that illustrates the two extreme plans and a plan that results from solving a linear model Data Initial conditions 300 workers, 500 units of inventory at Step 1 Gathering Project Information Gather a list of projects which are to be planned for the specified duration Collect highlevel estimates for the projects During the capacity planning phase, it is natural to not have detailed estimates and WBSThe idea here is that a level schedule is used during consistent periods and the chase strategy is used during months with fluctuating demand This can be helpful in seasonal business For example, a company that made Halloween chocolates, may maintain a level schedule for 9 months of the year and then use a chase strategy during the weeks

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Coronavirus S Impact On Supply Chain Mckinsey

Explain about the level capacity strategy Level capacity strategy The organisation produces or manufactures at a constant rate of output avoiding any changes or fluctuations within customer demand levels This frequently implies stockpiling or higher holdings of inventory while customer demand levels reduceSAMPLE – SURGE PLAN – "CODE YELLOW" DEFINITION This is a general Surge Plan and is based on two assumptions 1 Very specific activities would be initiated along with these guidelines dependent upon the nature of the disaster (CBRNEChemical,The Capacity Plan is used to manage the resources required to deliver IT services The plan contains scenarios for different predictions of business demand, and options with cost estimates to deliver the agreed service level targets

Could This Be The Easiest Way To Do Team Capacity Planning Kendis

Capacity Planning Everything You Need To Know Opensense Labs

Strategies The broad classes of capacity planning are lead strategy, lag strategy, match strategy, and adjustment strategy Lead strategy is adding capacity in anticipation of an increase in demand Lead strategy is an aggressive strategy with the goal of luring customers away from the company's competitors by improving the service level and reducing lead time Benefits of Resource Capacity Planner Template Excel spreadsheets are useful in many ways such as;A period's planned quantity of output is equal to that period's expected demand Level capacity strategy When an organization adopts the level capacity strategy then it manufactures at a constant output rate It does not consider any fluctuation or change in the level of demand

How To Do Capacity Planning Youtube

Capacity Plan Template Ms Office Templates Forms Checklists For Ms Office And Apple Iwork

It streamlines the resources management process It saves time It displays a summary sheet for a quick overview It saves money for getting the licensee of costly software It uses a pretty familiar and easily available excel spreadsheet toolLater, a need was identified to include provinciallevel staff members who are directly responsible for implementation 5 Monitoring and Evaluation of Capacity Building PlansThis point This capacity check looks at all resource capacities, not just bottlenecks The result of this process is a finalized material requirements plan The bottom level is where planning ends and execution takes over The material requirements plan results in

The Complete Beginners Guide To Agile Project Planning

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Capacity, Route Planning, and Scheduling An Efficient Trifecta Once you've got your highlevel (capacity) plan in place, you can use it as a guide for scheduling and route planning You'll want to use all three together to achieve the highest level of logistical efficiency We are here to help with all three Further, the key outcome of using a production capacity template excel spreadsheet is to keep the product inventory to a minimum level even fulfilling the customer demands So, good capacity planning for production results in a positive response to the fluctuation in product demand in different seasons over the product lifecycle

Workclout 3 Case Studies Examples Of Capacity Planning

1

Capacity Planning Operation Management Definition Types Steps Benefits With Example In Hindi Youtube

Capacity Planning An Overview Sciencedirect Topics

Checklist Capacity Plan It Process Wiki

What Is Capacity Management Role In Planning Marketing91

1

Capacity Planning Template Clicktime

Resource And Capacity Management

Level Capacity Plan Level Capacity Plan The Inventory Size Is Varied Keeping The Operation Management

Doc Capacity Planning Richa Verma Academia Edu

Demand And Capacity Management Decision Steps Download Scientific Diagram

Capacity Building Wikipedia

Capacity Planning Pdf Resource Strategic Planning

Could This Be The Easiest Way To Do Team Capacity Planning Kendis

Aggregate Capacity Planning Pdf Free Download

Solved When Using A Level Capacity Strategy Or Level Chegg Com

A Critical Insight To Successful Supply Chain Planning

Capacity Planning And Control

Pdf An Approach To Capacity Planning Of Distribution Warehouses For X Firm Semantic Scholar

Capacity Plan Template Technical Writing Tools

Project Management Templates Project Management Templates Project Management Tools Capacity Planning

Capacity Planning Organization System Examples Definition System Long Term Capacity Planning

5 Best Resource Capacity Planning Template Excel

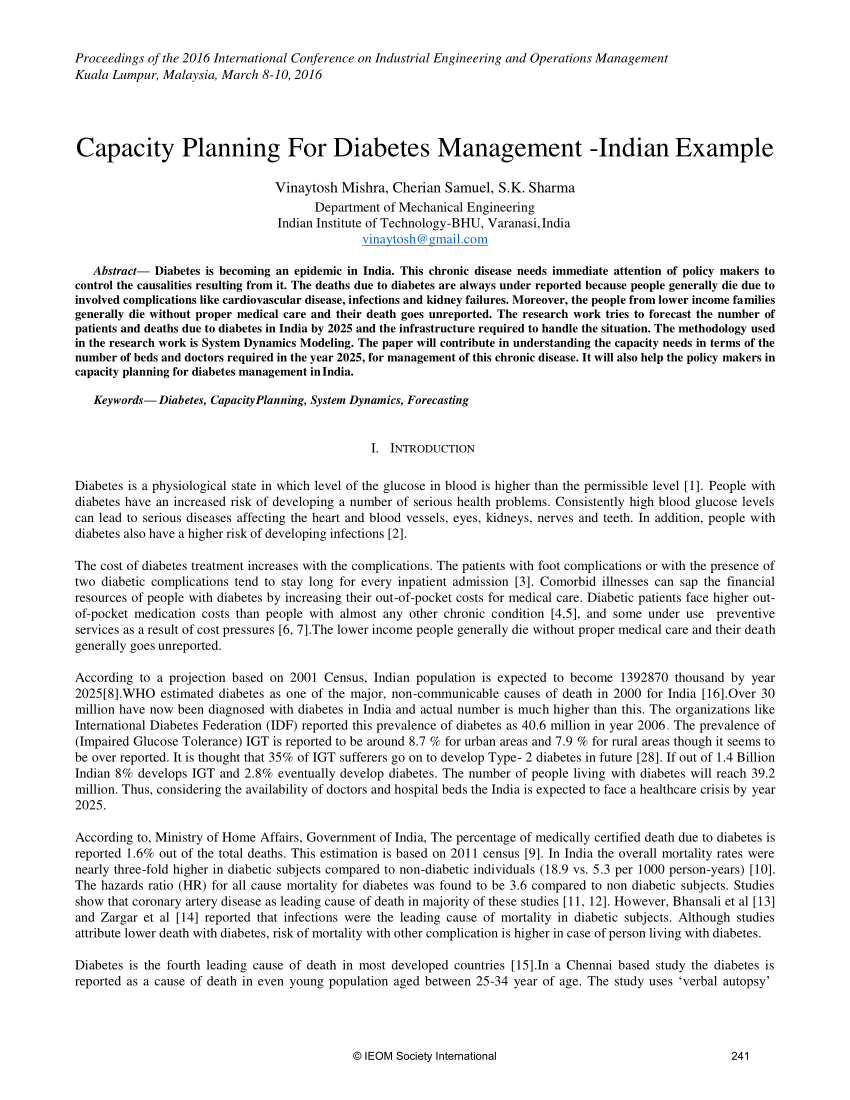

Pdf Capacity Planning For Diabetes Management Indian Example

Capacity Planning Template Atlassian

Capacity Planning 3 Methods How To Implement Them Optimoroute

Production Planning Meaning Importance Steps Example Mba Skool

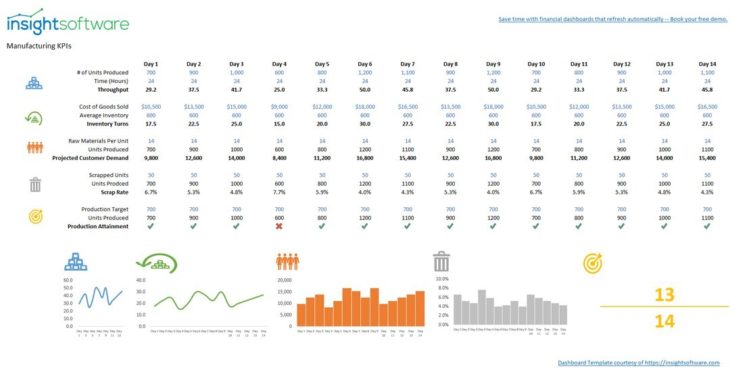

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

Master Production Schedule

Capacity Planning 3 Methods How To Implement Them Optimoroute

Set Sprint Capacity In Azure Boards Azure Boards Microsoft Docs

Sap Pp Capacity Planning Cm01 Cm21

5 Best Resource Capacity Planning Template Excel

Level Capacity Plan Ppt Powerpoint Presentation Pictures Background Cpb Presentation Graphics Presentation Powerpoint Example Slide Templates

3 Level Capacity Management Case Study

Match Supply And Demand In Service Industries

Mcse Prep Hardware Capacity Planning Intense School

Capacity Planning And Management Case Study Example Topics And Well Written Essays 1250 Words

Chapter 11 Capacity Management Ppt Video Online Download

Capacity Planning In Project Management 4 Vital Success Factors Update 21

Capacity Planning And Control Chapter 11 What Is

Aggregate Planning Chapter 11 Aggregate Planning Aggregate Planning

Capacity Planning What Is It And How Do I Implement It Projectmanager Com

Iteration Planning Scaled Agile Framework

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Capacity Planning Everything You Need To Know Opensense Labs

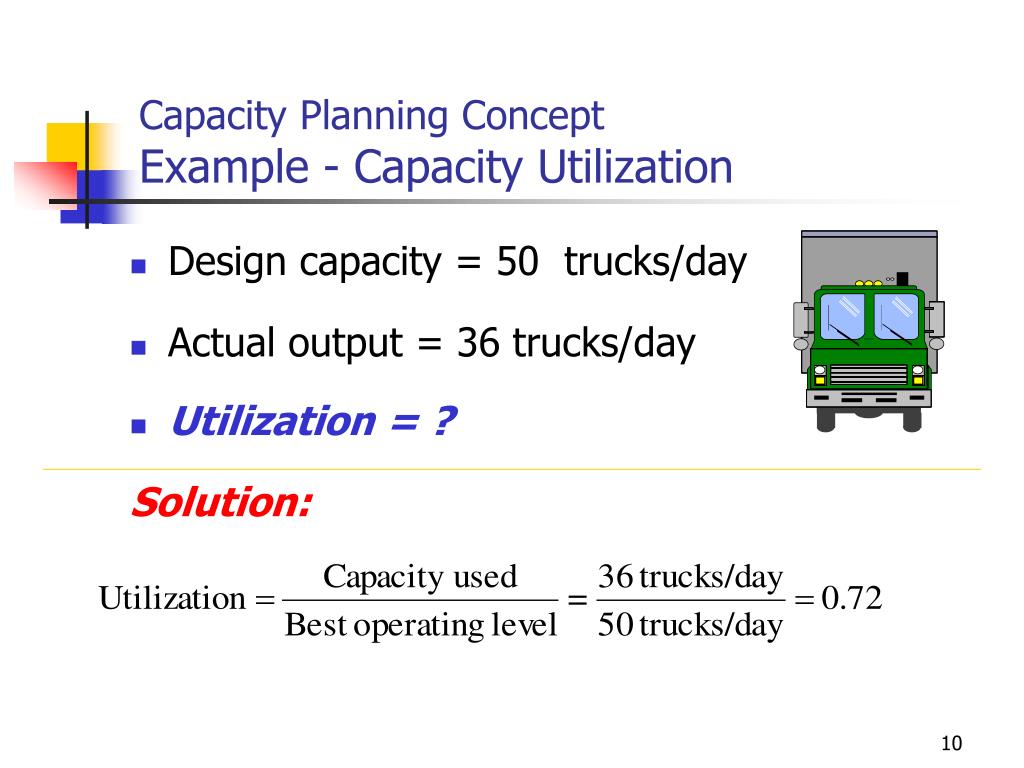

Capacity Utilization Definition Example And Economic Significance

Free Resource Planning Templates Smartsheet

What An Effective Capacity Planning Process Looks Like In 21

Capacity Planningcapacity Planning Long Rangelong Range Springerlink

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Ppt Mba 8452 Systems And Operations Management Powerpoint Presentation Id

Capacity Planning Example

Entries For Thursday 25 October 07 Sergio S Blog

Capacity Utilization Manufacturing Kpi Examples Sisense

How To Do Capacity Planning

Sap Pp Capacity Planning Cm01 Cm21

Capacity Planning What It Is How To Do It Well

Capacity Management At Infrastructure Level Part 1 Virtual Red Dot

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Maintenance Capacity Planning Ppt Video Online Download

1

1

Free Resource Planning Templates Smartsheet

Personal Consulting Capacity Essay Example Topics And Well Written Essays 2250 Words

The Goal Of Resource Capacity Management

Capacity Planning Template Example Unique Capacity Plan Template Download Microsoft Word And Excel Capacity Planning Stem Lesson Plans Lesson Plan Templates

Capacity Planning For Project Managers How To Plan Your Team S Time

4 Steps To Strategic Human Resource Planning Lucidchart

Capacity Planning Worksheet For Scrum Teams Agile Coffee

Capacity Planning Template Explore 7 Tips For Effective Planning Project Management Templates

Checklist Capacity Plan It Process Wiki

Capacity Planning And Management 2

Set Sprint Capacity In Azure Boards Azure Boards Microsoft Docs

Capacity Planning 3 Methods How To Implement Them Optimoroute

What Is Resource Leveling Techniques And Examples Asana

How Is Yield Management Implemented In Airline Industry Ayat Saleh

Capacity Planning Everything You Need To Know Clicktime

Aggregate Planning Chapter 11 Mis 373 Basic Operations Management Ppt Download

Rough Cut Capacity Planning Rccp Definition And 2 Types

Manage Resource Capacity Planning Scenarios

Capacity Planning Worksheet For Scrum Teams Agile Coffee

Aggregate Capacity Planning Pdf Free Download

0 件のコメント:

コメントを投稿